OUR PRODUCTS

Portland Composite Cement (PCC) 42.5N

“GREEN CEMENT”

The Portland Composite Cement (PCC) supplied by InnoCement is categorised as a “green” product due to its low carbon footprint. This is achieved through the replacement of high energy and carbon intensive clinker with fly ash, blast furnace slag and limestone during the production of the cement.

FULL COMPLIANCE TO MALAYSIAN & INTERNATIONAL STANDARDS

The product has been awarded the Product Certification License from SIRIM QAS International and Perakuan Pematuhan Standard (PPS) from Construction Industry Development Board (CIDB), a testament of its quality and full compliance to the Malaysian Standard, MS EN 197−1:2014.

HIJAU 50KG

The 50kg cement bag, wrapped in double- layer PP and craft paper, is designed for multiple handling, storage, and delivery making it ideal for small projects.

Fully Covered Sling Bag

Each sling bag contains 40 bags with a total weight of 2 MT. Our sling bag also comes FREE of charges. Its also help further reduce breakages.

Benefits of PCC 42.5N

Better Durability

Addition of Fly Ash & Blast Furnace Slag

These materials enhance the properties of the concrete.

Reduced Void & Permeability

The incorporation of fly ash and blast furnace slag reduces the void spaces within the concrete, which decreases its permeability.

Resistance to External Factors

With fewer voids and reduced permeability, the concrete becomes more resistant to penetration by external factors such as water, chemicals, and other potentially damaging substances.

Low Carbon Footprint

Clinker Replacement

PCC 42.5N uses over 30% replacement of clinker with supplementary materials like fly ash and blast furnace slag.

Environmental Impact

Clinker production is energy-intensive and emits a significant amount of CO2. By replacing a portion of clinker, the carbon footprint of the concrete is significantly lowered, contributing to more sustainable construction.

Better Workability

Ease of Handling

The concrete mix is more workable, meaning it can be easily mixed, transported, and compacted.

Construction Efficiency

Better workability facilitates easier and faster construction processes, potentially reducing labor costs and construction time.

Water/Cement Ratio

This improved workability is achieved while maintaining the lowest possible water/cement ratio, which is crucial for maintaining the strength and durability of the concrete.

Minimal Thermal Cracking During Mass Concreting

Low Heat of Hydration

The hydration process (the chemical reaction between cement and water) releases heat. PCC 42.5N emits lower heat due to its lower clinker content.

Reduced Thermal Cracking

High heat of hydration can lead to thermal cracking, especially in large concrete pours. By reducing this heat, PCC 42.5N minimizes the risk of thermal cracking enhancing the structural integrity and longevity of the concrete structure.

Applications of PCC 42.5N

PCC 42.5N can be used for a wide range of applications in concreting and masonry works. The presence of fly ash and blast furnace slag improve its durability and reduce its heat of hydration which make PCC42.5N suitable for marine structure and mass concreting works.

Concreting Works

- For the use in concrete, PCC 42.5N is suitable for producing various types of concrete grades in the construction of buildings, roads, and bridges.

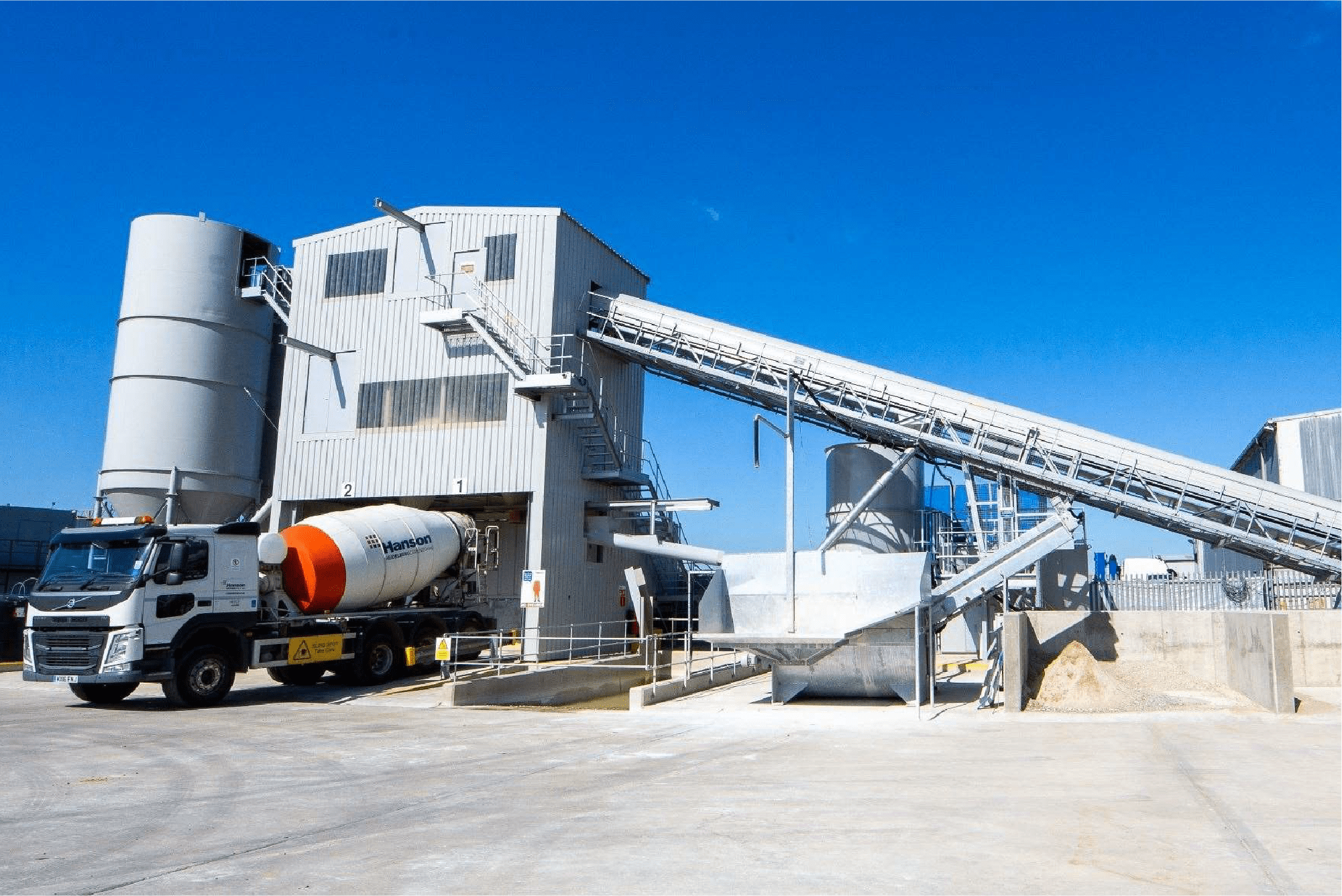

- Suitable for production of pre-cast and ready-mix concrete.

Masonry Works

- InnoCement's PCC 42.5N is suitable for use in a wide variety of masonry works such as for plastering, tile laying, brick laying, floor screeding and rendering.

- The availability of ground fine limestone improve water retentivity of the mix resulting in better plasticity and cohesiveness. It is very suitable for use in masonry works as it spreads easily under the trowel.

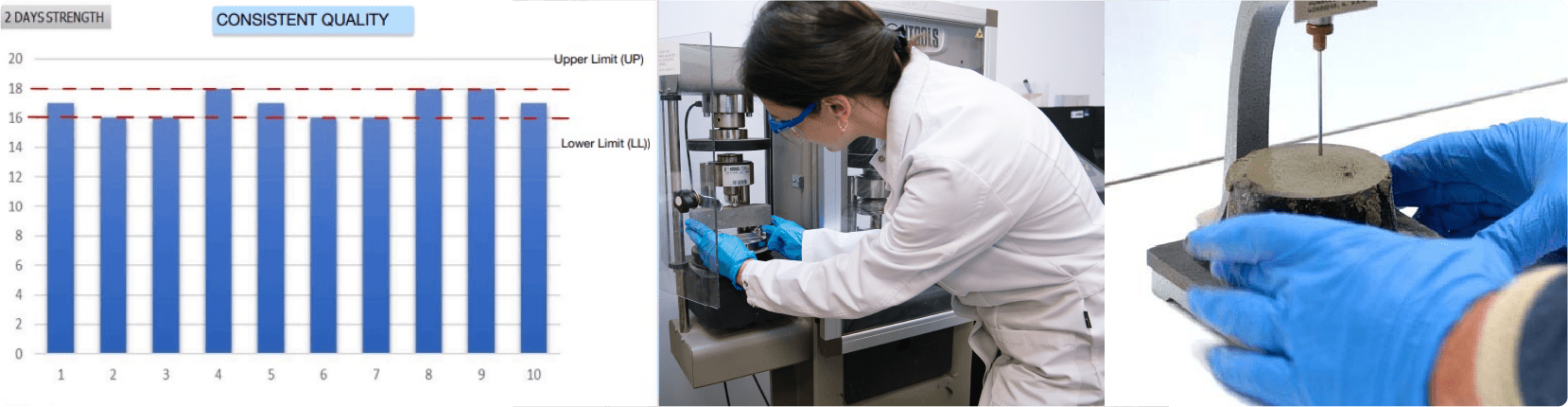

Typical Test Result

PARAMETER |

MS EN197−1 : 2014 REQUIREMENT |

TYPICAL RANGE |

|---|---|---|

|

Sulphate (%) |

≤ 3.5 |

2.1 - 2.3 |

|

Chloride (%) |

≤ 0.1 |

0.01 - 0.02 |

|

Compressive Strength |

≥ 10.0 |

16.0 - 18.0 |

|

Initial |

≥ 60 |

150 - 180 |

|

Soundness (mm) |

≤ 10 |

0.1 - 0.3 |

PARAMETER

REQUIREMENT

TYPICAL RANGE

Sulphate (%)

Chloride (%)

Compressive Strength

2 days (MPa)

28 days (MPa)

Initial

Setting Time (minutes)

Soundness (mm)

≤ 3.5

2.1 – 2.3

≤ 0.1

0.01 – 0.02

≥ 10.0

≥ 42.5

44.0 – 46.0

≥ 60

150 – 180

≤ 10

0.1 – 0.3